21.06.2022

Chức năng của bơm cánh quay NETZSCH

Độ dày công suất cao nhất, độ tin cậy tối đa và tính dễ bảo trì - đó chính là những gì mà bơm cánh quay của NETZSCH, hoạt động dựa trên nguyên lý thể tích dương, mang lại cho bạn. Chúng tôi sẽ giới thiệu cho bạn cách hoạt động của bơm cánh quay và lợi ích mà bạn có thể nhận được từ nó.

Rotary lobe pumps are self-priming valveless pumps that require very little space due to their design. In addition, they convince with continuous and gentle delivery and speed-proportional dosing of almost all media in the most diverse areas of application.

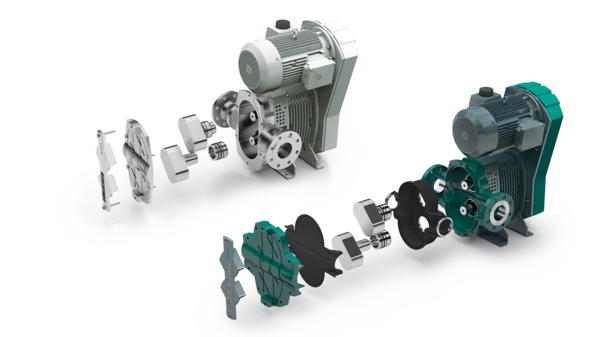

Essential components for the function

Tư vấn tùy chỉnh

A pump consists of countless individual parts. NETZSCH offers you a wide variety of designs for the food, pharmaceutical, chemical, industrial and oil and gas sectors. There are four elementary components for the function of the rotary lobe pump:

- Rotary lobes

- Pump housing

- Shaft seal

- Drive

In addition to all-metal rotary lobes, NETZSCH's portfolio also includes metal-rubber or rubber rotary lobes. The material and design of the rotary lobes are adapted to the unique requirements of the medium. Rotary lobes with suitable geometry are even available for viscous, abrasive and solids-containing materials. The optimal matching of the materials to the media increases the resistance and extends their service life. This means that you can benefit from the function of the rotary lobe pump in a wide range of applications. The associated shaft seal is also available in various designs: single-acting mechanical seals with Quench, SIC or other materials, and double-acting seals. The innovative FSIP® (Full Service In Place) design of the TORNADO® rotary lobe pumps from NETZSCH optimises the function of the pump and simplifies maintenance and servicing. You can change the rotary lobes in just a few steps because the lobes are not screwed to the shaft but are fixed with easily accessible clamping elements. In addition, no axial adjustment work is necessary on the rotary lobes. This saves you time and, consequently, money. The dead space-free design of the pump chamber also prevents product deposits. This makes cleaning much easier for you. Depending on the application profile, different drive variants are available. In addition to a belt-drive, NETZSCH also offers pumps with free driveshaft or power take-off shafts.

The function of the rotary lobe pump

Rotary lobe pumps are positive displacement pumps. The rotation of the lobes creates a vacuum on the suction side, which draws in the pumped medium. The lobes drive the medium along the pump wall into the pressure area. Two to six room fillings are displaced with one drive rotation, depending on the number of Rotorrotor,Rotors,rotorsrotor blades. This also allows you to dose in proportion to the speed. When the pump is at a standstill, rubber-coated rotors seal off the flow almost entirely and thus ensure that the rotary lobe pump functions smoothly. Lobes without rubber linings, on the other hand, are undersized to reduce friction, so a complete seal is not possible. The design of the pump also makes it insensitive to dry running and allows you to have fully functional pumping regardless of the direction of rotation.

Function and maximum operational reliability

Due to the unique separation between the pump and gear chamber, the TORNADO® pumps from NETZSCH offer you maximum operational safety. This means that no penetration of the medium into the bearing housing is possible in the case of a product leak. In addition, the innovative design allows you to inspect the mechanical seals visually. This enables you to react at an early stage if necessary. Thanks to the function of the rotary lobe pumps, you can also safely convey both low and high viscosity media. Due to the significant free ball passage and the low speeds, the positive displacement pumps are insensitive to blockages, clogging and foreign bodies. Varying solids contents have just as little influence on the flow rate as pressure changes. This enables continuous and powerful pumping.

Maximum economic efficiency due to rotary lobe pump

The revolutionary design of the TORNADO® delivery chamber increases the service life of the lobe and housing insert and the shaft seals in particular. The modular design also reduces your costs for replacing wear parts. In combination with improved efficiencies, this significantly reduces your life cycle costs.

Benefit from maximum serviceability and the highest power density of TORNADO® pumps from NETZSCH and optimise your process thanks to the function of a rotary lobe pump.